Injection Moulding Tool Materials

P20 Tool Steel

A pre-hardened tool steel is widely used for injection moulding tools.

Pros: Good machinability, decent wear resistance, affordable, suitable for medium-volume production.

Cons: Not ideal for extremely high-volume runs; may wear faster than hardened steels.

Stainless Steel (e.g., 420 or 440C)

Used when corrosion resistance is critical, such as for moulding corrosive plastics.

Pros: High corrosion resistance, good polishability (great for optical or medical parts).

Cons: More costly and brittle than standard tool steels; slower machining.

H13 Tool Steel

A hardened, high-performance steel used for high-volume or high-temperature moulding.

Pros: Excellent durability, heat resistance, and wear resistance. Suitable for aggressive materials, such as glass-filled plastics.

Cons: More expensive and more complex to machine than P20; longer lead times.

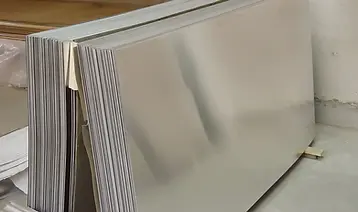

Aluminium (e.g., QC-10, 7075)

Used for prototype or short-run moulds.

Pros: Fast machining, cost-effective for low-volume runs, excellent thermal conductivity (faster cycle times).

Cons: Wears quickly, not suitable for abrasive materials or high-volume production.